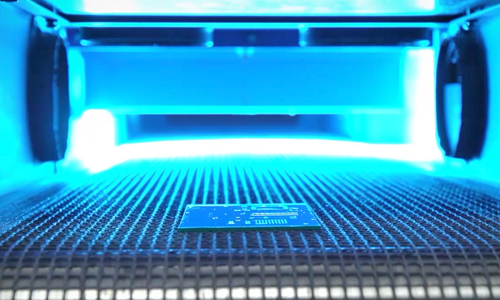

UV Conformal Coating is engineered to protect printed circuit boards (PCBs) with assembled electronic components. After application, it forms a thin and uniform protective layer that shields circuits from moisture, mold, salt spray, and chemical corrosion, ensuring stable performance even in harsh environments.

Read MoreUV peelable adhesive is a UV-curable solution developed for temporary surface protection where clean removal is essential.

Read MoreIn UV inkjet printing, most technical issues originate from ink formulation and material compatibility.

Read MoreBehind every premium privacy screen lies a UV privacy adhesive system designed to block side viewing while keeping the display bright and crystal clear.

Read MoreHigh-Refractive-Index UV Optical & Transfer Adhesives

Read MoreUV peelable adhesive is a UV-curable coating designed to provide reliable temporary protection during processing, assembly, and transportation.

Read MoreUV coating technology is a surface finishing process that uses ultraviolet light to instantly cure a liquid varnish applied to printed materials. Under UV irradiation, the coating undergoes a rapid chemical reaction, transforming from liquid to solid and forming a durable protective layer with the desired gloss or visual effect.

Read MoreDual-cure UV resin is designed for applications where consistent, reliable curing is essential—especially in environments where UV light cannot reach every area of the bonded interface.

Read MoreIn UV formulations, slow curing is often associated with low crosslink density, while cracking is linked to excessive crosslinking and internal stress.

Read MoreBut in reality, UV/EB curing has been safely used in industry for decades, supported by scientific research, engineering standards, and extensive field experience.

Read More

2022-08-03

2025-01-06

2022-07-06