Tackiness or stickiness may be noticed on the surface of some ultraviolet (UV) light-curable adhesives and coatings. This phenomenon, known as oxygen inhibition, is the result of atmospheric oxygen inhibiting the cure on the surface layer of the polymerizing material. This condition is present anytime free radical polymerization occurs. However, the ability of a UV resin to be cured "tack-free or to a slick, dry finish" is dependent on the composition of the adhesive or coating formulation and the intensity and wavelength of the UV light.

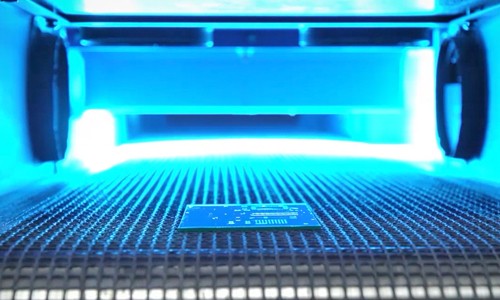

Overcoming the effects of oxygen inhibition and producing a tack-free surface cure is dependent upon several factors:

* Heat generated by the UV curing system

* Intensity generated over the entire UV spectrum (200-390 nm)

* Exposure time

* Specific formulation of the adhesive or coating

Typically, short and medium wavelength (220-320 nm) UV light generated by mercury vapor lamps achieve more efficient surface cures. Short and medium wavelength curing systems, however, do have depth of cure and safety issues associated with them making them an undesirable option for many UV curing applications. Longer wavelength (320-390 nm) systems, which usually emit a small fraction of UV light in the lower wavelengths, will provide fast, tack-free curing while achieving better depth of cure.

Time to cure “tack free” should not be confused with full cure time. It is only an indication of the material’s ability to overcome oxygen inhibition, at the surface of the curing material, when the material is exposed to a given level of light intensity for a specific period of time. It has been demonstrated that the higher the intensity of the UV light the lower the total energy level needed to achieve a "tack free" surface. For example, to produce a tack-free surface cure of a Dymax conformal coating (984-LVUF) using a 200 mW/cm2 light source, the coating should be exposed for 20-30 seconds. This equals approximately 7 J/cm2 of energy. This same coating cures in 1-2 seconds when exposed to 2,500 mW/cm2 equaling 2.5 J/cm2 of energy.

Even though removing oxygen from the surface will also work at achieving a tack-free surface, this tends to be the least desirable method since it can be logistically challenging to implement.

We can answer your questions!

Welcome to visit our "Made in China" plateform,by clicking here.

#resin #UVresin #chinaresin #chinapolyurethane #resinmaterial #plasticresin #uvoil #uvpigment #whitepolyurethaneresin #polyurethaneresinadhesive #adhesive #polyurethaneresinfoam #uvreinbulkbuy

2022-08-03

2025-01-06