"Demand is steadily rising due to environmental factors and the need for increased productivity and lower applied cost," said Ben Curatolo, director of technology, UV Coatings Limited, Berea, OH.

"The benefits of UV/EB systems, no VOC, very fast cure and low energy requirements, make the technology very attractive," said Jim Yosh, business manager, Tego Chemie Service.

Once known as a coatings system offering mainly environmental benefits, rad-cure technology now also boasts improved performance properties that make it a viable alternative to other coatings systems.

"Environmental reasons are still a dominant reason for choosing a UV cured coating, though the productivity benefits of their fast cure time are equally important," said Clai Bachmann, senior vice president, marketing and communications, Dymax Corporation, a manufacturer of conformal coatings for the protection of printed circuit boards. "Even with the higher cost per pound of the UV coatings, all of the savings in time, labor, energy and lower use of plant space often make them the much more economical choice."

"Green technology will always be important, but we are also seeing the UV/EB industry focus on the enabling properties," said Chris Bradford, senior technical service representative, BASF automotive OEM coatings group. "UV/EB enables the end-user to develop balanced properties and processes that no other technology can approach. UV/EB is truly an enabling technology."

Jim Raymont, director instrument markets, EIT, said another factor driving growth of rad-cure coatings is the availability of better finished products that may offer increased durability and higher gloss. "UV products are also allowing end-users to achieve greater productivity," he said.

Ramesh Narayan, commercial development manger, Cognis energy cure chemicals, added, "Product performance, increased productivity and throughput, lower capital (space and equipment) requirements to start new facilities and significantly lower waste disposal costs are also key drivers for growth in this market."

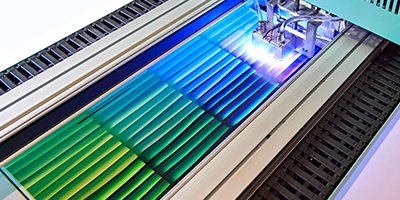

Continued improvements in equipment used with UV/EB coatings have also made the technology more attractive to end-users.

"In the past, the acceptance of UV and EB systems were limited by 'mechanical' constraints," said Mr. Yosh. "The industry grew up around flat stocks where the curing lamps could be aimed directly down on the substrate being coated and cured. As time has passed, coatings and equipment manufacturers have worked together to eliminate many of the shadow cure problems of the past. This opened the industry to applications as numerous as the coatings industry itself."

"Another growth driver has been the development of dispensing and sensing equipment that allows precisely controlled placements of the coatings," said Ms. Bachmann. "In the case of conformal coatings, this means that waste is virtually eliminated. Since the materials do not contain solvents, there is no need for expensive ventilation and reclamation equipment."

A good illustration of the technology's continued growth comes from Star Technology. According to Donn R. Starkey, president of the Waterloo, IN-based coatings manufacturer, in 1990, approximately one out of 20 inquiries were for a UV product. "That has now changed to about one out of two inquiries," he said.

Forwarded from COATING WORLD

For chemical raw material for UV coatings, welcome to visit our "Made in China" plateform,by clicking here.

#resin #UVresin #chinaresin #chinapolyurethane #resinmaterial #plasticresin #uvoil #uvpigment #whitepolyurethaneresin #polyurethaneresinadhesive #adhesive #polyurethaneresinfoam #uvreinbulkbuy

2022-08-03

2025-01-06