UV Conformal Coating is engineered to protect printed circuit boards (PCBs) with assembled electronic components. After application, it forms a thin and uniform protective layer that shields circuits from moisture, mold, salt spray, and chemical corrosion, ensuring stable performance even in harsh environments.

By isolating solder joints and conductors from external contaminants, the coating significantly improves insulation performance, reduces the risk of short circuits, and helps suppress electromagnetic interference (EMI), extending the service life of electronic assemblies.

UV Conformal Coating is also known as PCB conformal coating, three-proof coating, insulating varnish, protective coating, electronic coating material, or moisture-resistant coating, and is widely accepted across the electronics manufacturing industry.

Traditional solvent-based coatings contain high levels of VOCs, releasing harmful emissions during curing. UV dual-cure conformal coatings feature 100% solid content with zero VOC emissions, making them an environmentally responsible choice that complies with modern green manufacturing standards.

Unlike conventional coatings that require hours to fully cure, UV dual-cure systems achieve surface drying and initial curing within seconds under UV light. This dramatically increases production throughput and supports high-speed automated manufacturing lines.

UV curing requires significantly less energy than thermal baking processes. Reduced power consumption, combined with minimal equipment maintenance, helps manufacturers lower long-term operating costs.

The dual-cure mechanism combines rapid UV curing with moisture-activated post-curing. While exposed areas cure instantly under UV light, hidden zones such as connector bases and component gaps continue to cure through ambient moisture, ensuring complete and reliable protection.

Designed for demanding applications, UV conformal coatings maintain stable performance across a wide temperature range from -40°C to 130°C, meeting the requirements of most electronic products.

Brush coating is ideal for small batches and detailed work. Using natural fiber brushes ensures smooth, even coverage on flat PCB surfaces with minimal material waste.

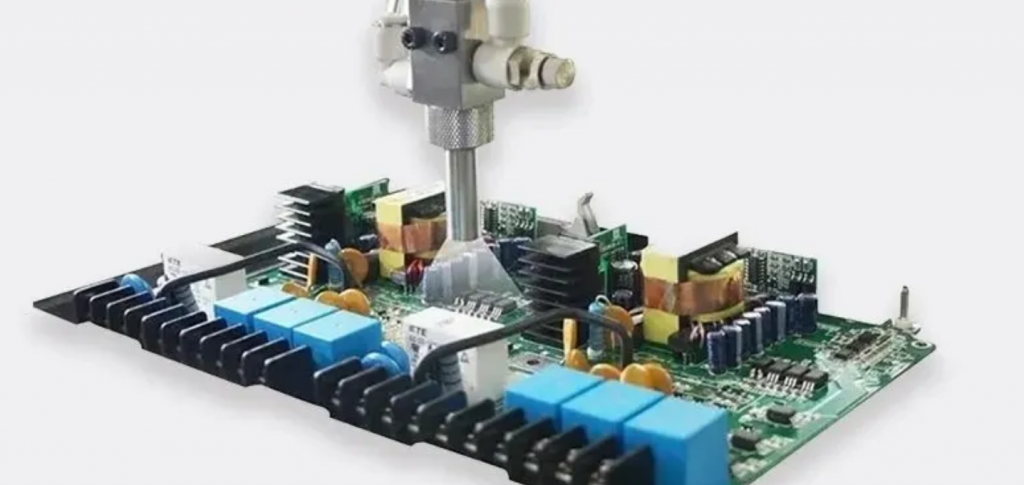

Spray coating is suitable for both maintenance tasks and large-scale production. Proper control allows for uniform coverage, though careful operation is required to avoid shadowing under components.

Dip coating ensures complete and uniform film formation over the entire PCB surface, eliminating missed areas while reducing material waste caused by overspray.

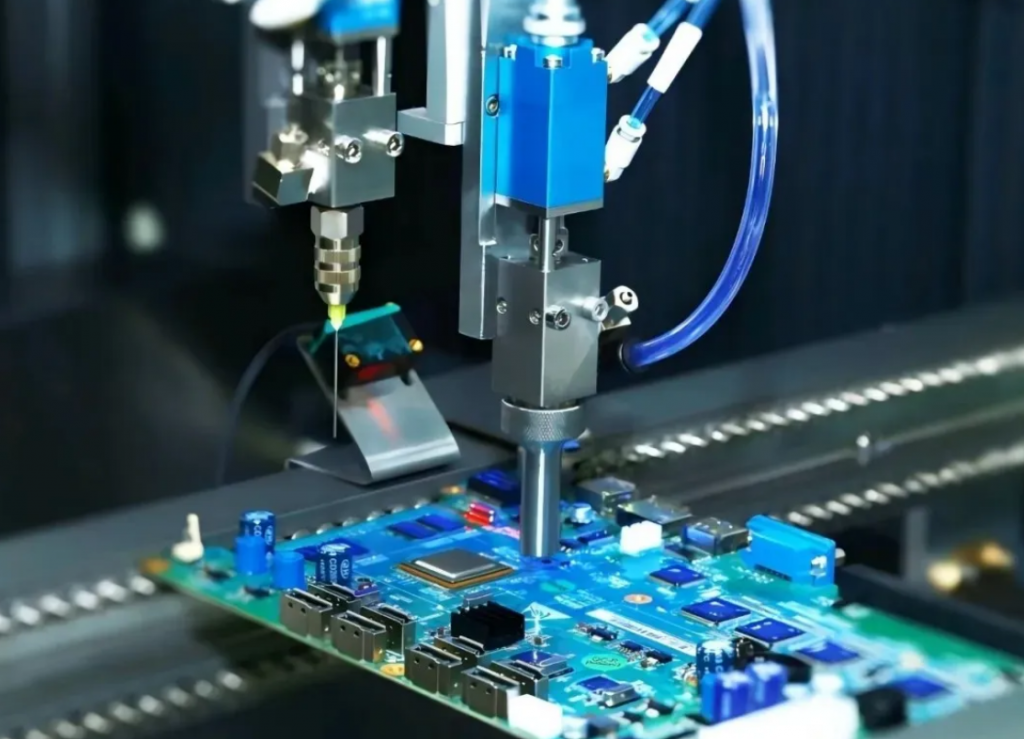

Selective coating delivers precise application only where needed, maximizing material efficiency and consistency. It is ideal for mass production but requires advanced automated equipment.

Cleaning and pre-baking remove moisture, dust, and oils from PCB surfaces, ensuring optimal adhesion and coating performance. Applying the coating while the board is still warm improves coverage and bonding.

Maintaining a coating thickness between 0.1 and 0.3 mm ensures effective protection without affecting component functionality or heat dissipation.

Fully mixing the coating and allowing it to stabilize before use helps achieve consistent viscosity and coating quality, whether applied manually or through automated systems.

Moisture curing is driven by the reaction between isocyanate (-NCO) groups and water molecules. This process forms a crosslinked network that strengthens the coating from the inside out, especially in areas not reached by UV light.

Curing performance depends on temperature and humidity. For best results, coating operations should be conducted at temperatures above 16°C and relative humidity below 75%.

Protects circuit boards in household appliances and commercial devices from moisture, insects, and everyday contaminants.

Provides long-term protection against fuel vapors, salt spray, brake fluids, and vibration in automotive electronic systems.

Ensures reliable circuit performance under extreme pressure changes and harsh operating environments.

Shields electronic systems from fresh and saltwater exposure in maritime applications.

Widely used in LED displays, power supplies, inverters, solar systems, instruments, and consumer electronics requiring durable environmental protection.

#UVConformalCoating #PCBConformalCoating #UVDualCureCoating #ElectronicCoating #PCBProtection #ZeroVOC #FastUVCuring #DualCureTechnology #MoistureResistant #ChemicalResistant #HighInsulation #EMIProtection #BrushCoating #SprayCoating #DipCoating #SelectiveCoating #ConsumerElectronics #AutomotiveElectronics #IndustrialElectronics #LEDProtection #EcoFriendlyCoating #RoHSCompliant

2022-08-03

2025-01-06