Dual-cure UV resin is designed for applications where consistent, reliable curing is essential—especially in environments where UV light cannot reach every area of the bonded interface. By combining UV-initiated polymerization with a secondary thermal or moisture-curing mechanism, these systems deliver full-depth curing, excellent bond strength, and stable long-term performance across a wide range of substrates.

1. Complete Cure in Shadowed Areas

In assemblies with complex geometries, deep cavities, or opaque components, UV light alone is not sufficient to achieve a uniform cure. Dual-cure systems activate a secondary curing pathway that ensures the resin fully polymerizes, eliminating concerns about soft spots, incomplete bonding, or reduced mechanical integrity.

2. Rapid UV Fixation for Production Efficiency

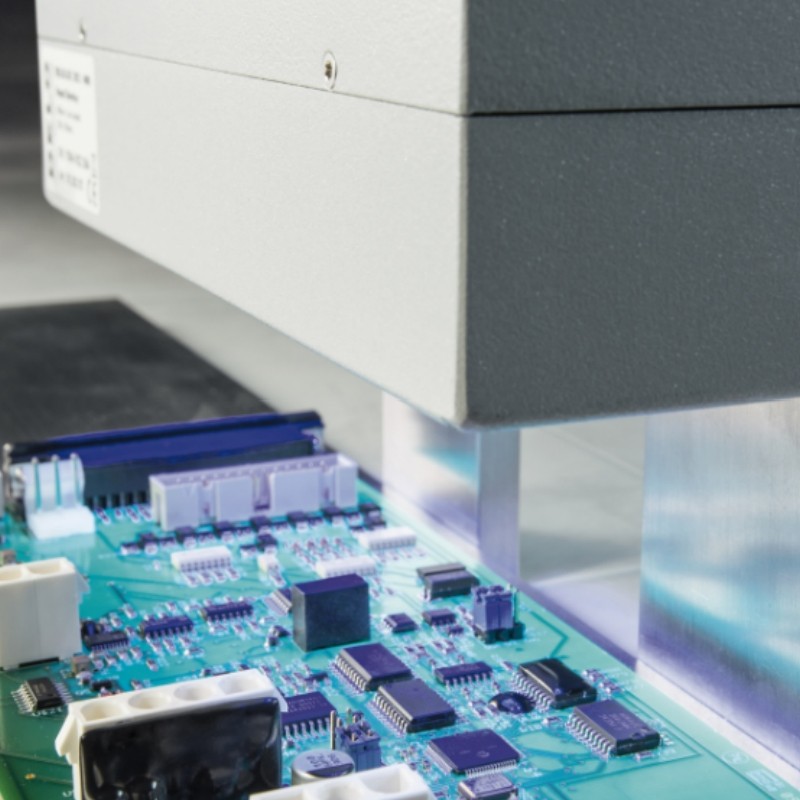

The UV stage offers immediate surface cure and initial handling strength, enabling fast alignment, reduced clamping time, and improved throughput on automated production lines. This balance of speed and reliability makes dual-cure resins suitable for high-volume manufacturing.

3. High Adhesion and Environmental Resistance

Engineered for demanding industrial environments, dual-cure UV resins exhibit strong adhesion to metals, plastics, glass, ceramics, and composite materials. Their cured networks typically provide excellent resistance to heat, humidity, vibration, and chemical exposure—key requirements in electronics and automotive applications.

4. Flexible Processing Conditions

Whether used in UV-only mode, thermal cure mode, or a hybrid approach, dual-cure systems offer exceptional process flexibility. Manufacturers can optimize curing conditions to meet specific design constraints, equipment capabilities, or substrate compatibility.

Dual-cure UV resin is increasingly adopted across industries that require high precision and dependable performance:

Electronics: bonding optical modules, sensors, micro-speakers, and structural components

Automotive: structural bonding, component encapsulation, headlamp assembly

Industrial manufacturing: glass-to-metal bonding, composite joining, protective coatings

Optoelectronics: fiber optic components, lens assembly, precision alignment fixtures

Choosing the right dual-cure UV resin depends on factors such as optical properties, thermal resistance, viscosity profile, cure speed, and substrate type. Advanced formulations offer low shrinkage, high clarity, and stable performance under harsh operating conditions, making them suitable for both micro-assembly and larger structural applications.

For manufacturers looking to improve reliability in complex assemblies or enhance production efficiency, dual-cure UV resin provides a robust, high-performance alternative to traditional single-cure systems.

#DualCureUVResin #UVResin #DualCureAdhesive #UVAdhesive #LightCureAdhesive #UVThermalCure #AdvancedMaterials #IndustrialAdhesives #ElectronicsBonding #Optoelectronics #PrecisionAssembly #UVCuringTechnology #HighPerformanceResin #EngineeringMaterials #ManufacturingSolutions #AutomotiveAdhesives #GlassBonding #OpticalBonding #MaterialsScience #IndustrialChemicals

2022-08-03

2025-01-06