UV coatings are increasingly replacing traditional coatings across various industries due to their numerous advantages, such as rapid curing times, environmental benefits, and superior durability. In this article, we’ll compare UV coatings with traditional solvent-based and thermoset coatings and explore their unique applications in different industries.

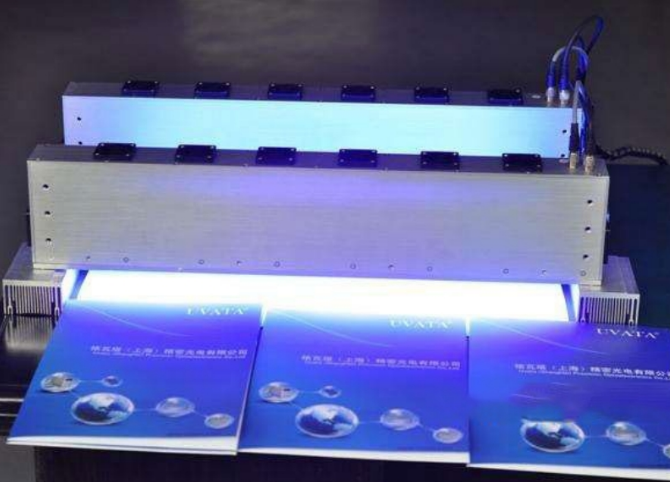

One of the key benefits of UV coatings is their extremely fast curing process. UV coatings cure instantly when exposed to ultraviolet light, making them ideal for high-speed production environments. This rapid curing reduces drying time significantly compared to traditional coatings, enhancing productivity and reducing energy consumption.

UV coatings are considered eco-friendly because they do not require solvents. Traditional coatings, such as solvent-based formulations, emit volatile organic compounds (VOCs) during application, which are harmful to both the environment and human health. UV coatings, on the other hand, are typically 100% solids and release little to no VOCs, contributing to better air quality and a safer working environment.

UV coatings offer excellent chemical resistance, making them ideal for applications where exposure to harsh chemicals is common. This is particularly advantageous in industries such as automotive, electronics, and packaging, where coatings need to withstand chemicals, oils, and cleaners without degrading.

Solvent-based coatings have been a traditional choice for many years. They rely on solvents to dissolve the resin, making the application process smoother. However, these coatings come with several disadvantages:

Longer Drying Time: Solvent-based coatings require time to dry through evaporation, which can lead to longer production times.

VOC Emissions: As mentioned earlier, solvent-based coatings release harmful VOCs, contributing to air pollution.

Lower Durability: While solvent-based coatings offer some resistance to chemicals, they generally lack the same level of durability and chemical resistance as UV coatings.

UV coatings outperform solvent-based coatings in speed, environmental impact, and durability. They are ideal for applications where both speed and sustainability are critical.

Thermoset coatings are another traditional coating option that undergoes a chemical reaction when heated, resulting in a cross-linked structure. This type of coating offers good durability and chemical resistance, similar to UV coatings. However, thermoset coatings have several drawbacks:

High Energy Consumption: Thermoset coatings require curing at high temperatures, which consumes more energy and increases production costs.

Longer Cure Times: Unlike UV coatings that cure instantly under UV light, thermoset coatings require prolonged heating, reducing production efficiency.

UV coatings provide a more energy-efficient and faster alternative, while maintaining superior performance characteristics similar to thermoset coatings.

UV coatings are used across a wide range of industries due to their unique benefits. Here are some common applications:

In the printing industry, UV inks and coatings are used to produce high-quality prints on various substrates. They are ideal for screen printing, offset printing, and digital printing applications. UV coatings provide excellent gloss, scratch resistance, and durability, making them perfect for packaging, labels, and printed materials.

UV coatings are widely used in the automotive industry for both interior and exterior applications. These coatings offer excellent protection against scratches, chemicals, and UV radiation. They are used on automotive parts, trim, and dashboards to enhance durability and appearance.

In the furniture and woodworking industries, UV coatings are commonly used for furniture finishes, flooring, and cabinetry. They provide a smooth, glossy finish and offer superior protection against wear and tear, moisture, and chemicals.

UV coatings are also used in electronics manufacturing, particularly for coating circuit boards and other electronic components. The fast curing time and chemical resistance of UV coatings ensure long-lasting protection for sensitive electronic parts.

UV coatings are ideal for packaging applications, particularly for food and beverage packaging. They provide a shiny, attractive finish that enhances product presentation, while also offering protection against moisture, chemicals, and wear.

UV coatings provide numerous advantages over traditional solvent-based and thermoset coatings, including rapid curing, environmental benefits, and superior durability. Their ability to cure instantly under UV light makes them ideal for high-speed production processes, while their low VOC content makes them an eco-friendly choice. Whether in printing, automotive, wood coatings, electronics, or packaging, UV coatings offer superior performance in a wide range of applications, setting them apart from traditional coatings. As industries continue to prioritize sustainability and efficiency, UV coatings are expected to play an even greater role in the future of manufacturing and product design.

#UVCoatingTechnologyInsights #BenefitsOfUVCoatingInIndustry #TopApplicationsForUVCoating

#UVCoatingVsConventionalFinishes #UVCoatingInAutomotiveIndustry #UVCoatingProcessStepByStep

#InnovationsInUVCoatingMaterials #CostEffectivenessOfUVCoating #UVCoatingForOutdoorDurability

#SustainableAspectsOfUVCoating

2022-08-03

2025-01-06