UV coatings have gained immense popularity due to their fast curing times, excellent durability, and environmentally friendly properties. However, the performance and application of UV coatings can be significantly enhanced by the use of specific additives. These additives play a critical role in improving coating properties such as flow, leveling, adhesion, and foam control.

In this article, we’ll delve into the key types of UV additives, their role in various applications, and tips for selecting the right additives for UV coatings.

Flow agents are essential for ensuring a smooth, uniform surface finish in UV coatings. They improve the flow and leveling properties of the coating, minimizing surface defects such as brush marks or roller lines. These agents ensure that the coating spreads evenly across the substrate, preventing the formation of bubbles or imperfections during application.

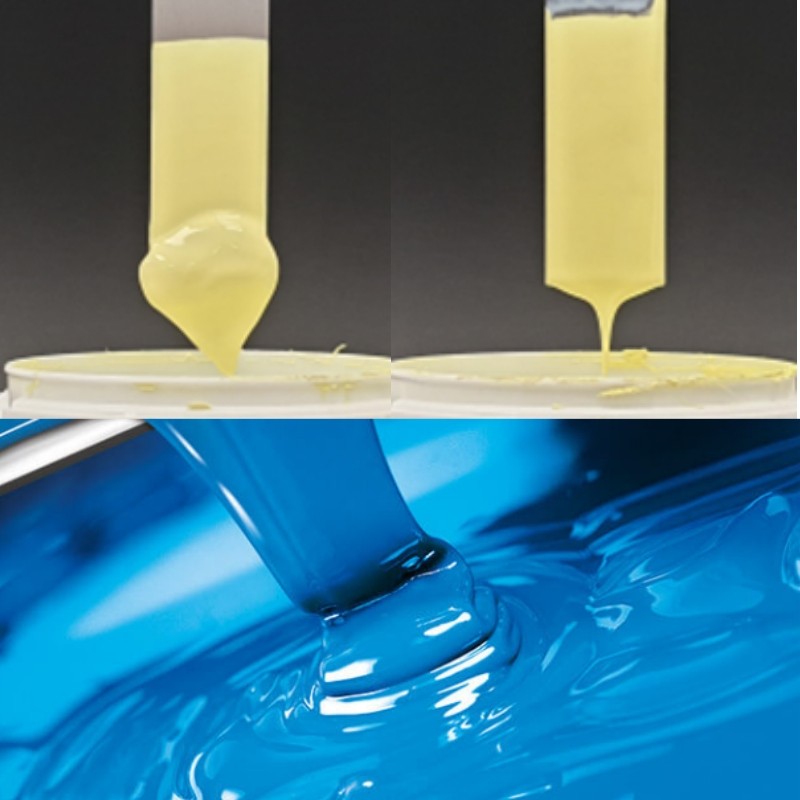

Defoamers are crucial for controlling foam formation during the mixing, application, and curing process of UV coatings. Foaming can lead to defects like air bubbles or uneven coating thickness. Defoamers effectively reduce foam, ensuring a smoother finish and better adhesion. In addition, they help prevent defects during the curing process, ensuring a flawless final product.

Adhesion promoters are additives designed to enhance the adhesion of UV coatings to a variety of substrates, including metals, plastics, and glass. They improve the bonding between the coating and the surface, ensuring long-lasting durability and resistance to environmental stressors. These additives are especially valuable for coatings applied to substrates with low surface energy or challenging surfaces like plastics or metals.

UV inks, widely used in screen printing and offset printing, require excellent flow and leveling properties to ensure sharp, consistent prints. Flow agents help prevent ink smudging or uneven application, while defoamers eliminate air bubbles that could ruin the print quality. Adhesion promoters are essential for inks used on non-porous surfaces such as plastics or glass, where proper bonding is crucial for durability.

In the wood coating industry, flow and leveling agents are used to ensure a smooth, even finish that enhances the natural beauty of the wood. Defoamers are also essential in wood coatings to prevent air bubbles during the application process, ensuring a high-quality finish. Adhesion promoters are important for improving bonding to wood surfaces and ensuring the coating remains intact over time, resisting peeling or cracking.

Plastic coatings, particularly for items like packaging, automotive parts, and consumer goods, benefit greatly from the addition of adhesion promoters. These help to ensure that the coating adheres to the plastic surface, which can otherwise be difficult due to its low surface energy. Flow agents ensure that the coating covers the plastic evenly without streaking or defects, while defoamers reduce foaming during the curing process, ensuring an optimal finish.

Selecting the right UV additives for your coating formulation is crucial for optimizing performance. Here are a few tips to help guide your choices:

Different substrates have different requirements for adhesion. Always choose adhesion promoters that are tailored to the specific material you are coating (e.g., plastics, metals, wood).

Consider Application Method: The method of application (e.g., brush, roller, spray) will impact the flow and leveling requirements of the coating. Choose flow agents that are compatible with the chosen application technique.

UV coatings are cured by UV light, and some additives can affect curing efficiency. Ensure that any additives you select will not interfere with the curing process, ensuring a quick and complete cure.

Not all additives work well together. Before scaling up production, always test the compatibility of your selected additives with the other ingredients in your coating formulation to avoid any unwanted reactions or performance issues.

Additives play an integral role in enhancing the performance of UV coatings. By selecting the right flow agents, defoamers, and adhesion promoters, manufacturers can significantly improve the application, durability, and aesthetic appeal of their UV coatings.

Whether used in inks, wood coatings, or plastic coatings, these additives ensure that UV coatings meet the demanding requirements of various industries.By carefully selecting the appropriate additives for each application, manufacturers can optimize their UV coatings for both performance and quality, ensuring customer satisfaction and long-lasting results.

2022-08-03

2025-01-06