UV monomers play a crucial role in determining the final properties of UV-curable coatings. By adjusting viscosity, hardness, and adhesion, these monomers allow formulators to optimize coatings for different applications.

UV monomers serve as reactive diluents that:

·Reduce Viscosity: Lowering the viscosity of UV formulations improves processability and ensures smooth application.

·Adjust Hardness and Flexibility: The choice of monomer influences the final coating’s mechanical properties, from hard and scratch-resistant to soft and flexible.

·Improve Adhesion: Certain monomers enhance bonding to substrates like plastics, metals, and glass, ensuring durability and performance.

Acrylate Monomers

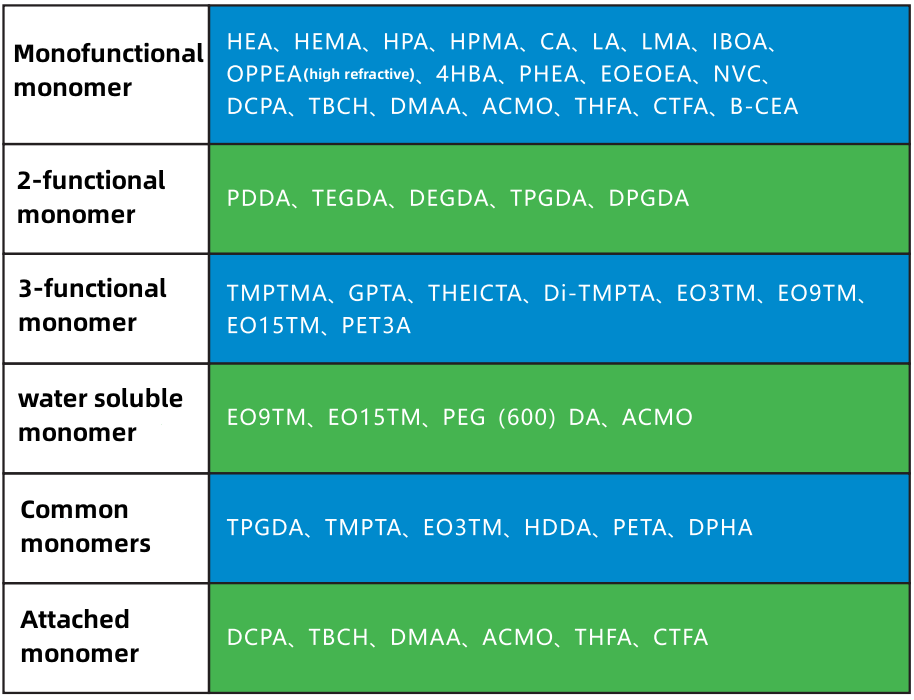

Mono-functional Acrylates: Provide flexibility and good adhesion but may have slower curing speeds.

Di-functional and Tri-functional Acrylates: Offer a balance between flexibility and hardness.

Multi-functional Acrylates: Enhance crosslinking, resulting in highly durable and scratch-resistant coatings.

Epoxy-Based Monomers

Known for high adhesion and chemical resistance, epoxy acrylates are widely used in industrial coatings and adhesives.

Urethane Acrylates

These monomers provide excellent flexibility, impact resistance, and durability, making them ideal for high-performance coatings.

Selecting the right monomer depends on:

Application Requirements: Consider whether the coating needs flexibility, hardness, or high adhesion.

Curing Speed: Higher functionality monomers cure faster but may lead to increased brittleness.

Substrate Compatibility: Ensure strong adhesion to the target material.

Regulatory Compliance: Some industries require low-VOC, non-toxic formulations.

UV monomers are essential in tailoring coating properties for different applications. By selecting the right type and concentration, manufacturers can optimize viscosity, hardness, adhesion, and curing performance, ensuring high-quality and durable UV coatings.

#UVMonomers #UVResinMonomers #UVCuringMonomers #UVCoatingMonomers

#UVPhotoinitiatorMonomers #LowVOCUVMonomers #HighPerformanceUVMonomers

#UVMonomerCrosslinking #MonomersInUVCoeatings #UVMonomerApplications

#UVMonomerMarketTrends

2022-08-03

2025-01-06