During UV coating or molding processes, coatings or molded parts often stick to the mold or surface, making demolding difficult. This not only affects production efficiency but can also damage the surface quality of the product.

A UV release agent is a functional additive that helps reduce surface adhesion between coatings and molds or substrates. By forming a thin, uniform layer, it makes the release process smoother, cleaner, and more consistent.

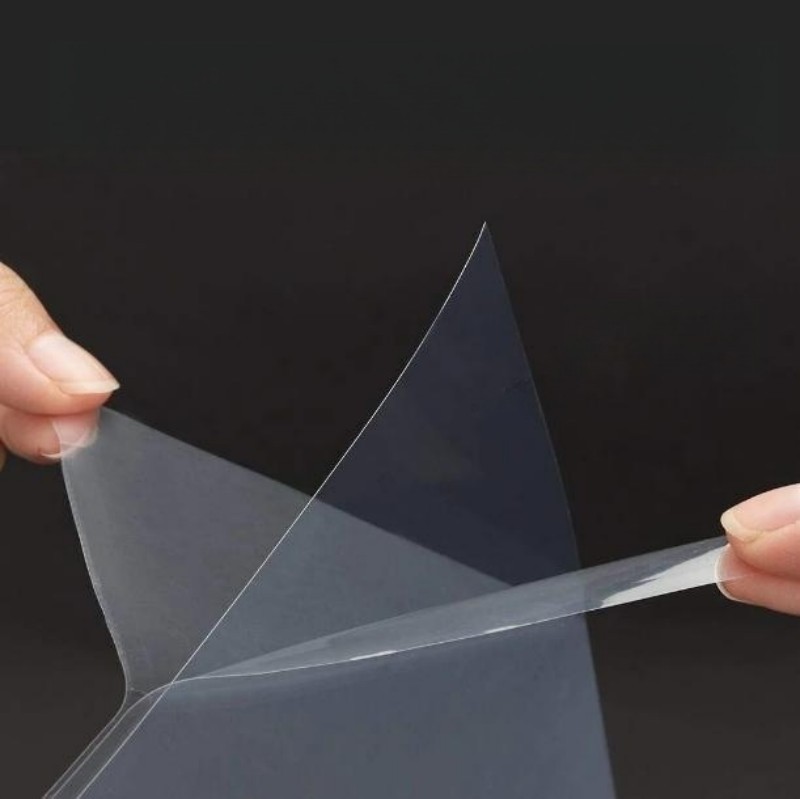

With the right release agent, products can be separated easily without sticking, tearing, or residue. This minimizes surface damage and reduces the number of defective parts—saving time, material, and labor.

UV release agents are designed to work seamlessly with UV-curable coatings and inks. They do not affect curing speed, gloss, transparency, or surface smoothness, making them easy to integrate into existing formulations.

Unlike traditional release aids that may leave marks or residues, high-quality UV release agents ensure clean separation. The result is a smooth surface finish with excellent visual and functional properties.

UV release agents are widely used in electronics, automotive, packaging, decorative films, and various precision molding processes. Their stable performance makes them a trusted solution in high-demand production lines.

Only a small amount of UV release agent is needed to make a significant difference. This simple additive step can improve production efficiency, extend mold life, and help maintain consistent product quality.

A clean release means less downtime, fewer rejects, and more efficient operations. Choosing the right UV release agent can elevate both product quality and production stability.

#UVcoating #UVReleaseAgent #ReleaseAdditive #MoldRelease #UVCuring #SurfaceTreatment #CoatingTechnology #IndustrialCoatings #ManufacturingSolutions #CoatingAdditives

2022-08-03

2025-01-06