Shrinkage is a common challenge in UV coatings, adhesives, and resins, and it can significantly impact the performance and appearance of the final product. As UV formulations cure, they often experience dimensional changes, leading to issues such as surface distortion, poor adhesion, and reduced product quality. Understanding the causes of shrinkage and exploring strategies to reduce it are crucial for manufacturers seeking high-performance UV products. This article will explore the causes of shrinkage, the selection of low-shrinkage resins and monomers, and formulation optimization techniques to minimize shrinkage in UV formulations.

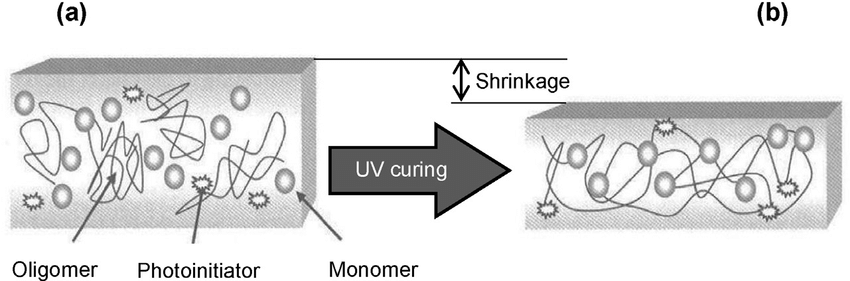

UV coatings and resins undergo a curing process that involves the polymerization of monomers and oligomers, often resulting in a volume reduction or shrinkage. Shrinkage is a natural consequence of the curing reaction, but it can cause several issues that affect the final product’s appearance and functionality.

The primary cause of shrinkage in UV formulations is polymerization. During the curing process, monomers (small molecules) polymerize to form larger polymer chains. This chemical transformation typically leads to a decrease in volume, as the molecular structure becomes more densely packed. The extent of shrinkage depends on the formulation and the degree of conversion (i.e., how fully the monomers have polymerized). High shrinkage rates can distort the surface of the coating or adhesive, leading to cracking, peeling, and poor adhesion.

Although UV curing is typically achieved through exposure to light rather than heat, some UV formulations may still experience heat-induced shrinkage. This happens due to the exothermic nature of the curing reaction, where heat is generated during polymerization. The heat may cause the resin or coating to contract, contributing to additional shrinkage.

The type of substrate also affects shrinkage. For example, flexible substrates may deform due to the shrinkage of the UV coating or adhesive, whereas rigid substrates may create internal stresses, leading to cracking or delamination. Shrinkage is more pronounced on substrates that are sensitive to changes in dimension, such as films or soft plastics.

#UVShrinkage #PolymerizationShrinkage #UVCuringShrinkage #UVResinShrinkage #LowShrinkageUV #ShrinkageControl #UVCoatingDefects #UVAdhesiveIssues #UVFormulation #ShrinkageReduction #UVFormulationOptimization #Photopolymerization #ReactiveDiluents #FreeRadicalPolymerization #AcrylateMonomers #UVCoatingTechnology #ExothermicReaction #DimensionalStability #UVResinCracking #AdhesionFailure

2022-08-03

2025-01-06