Improving adhesion in UV coatings requires a holistic approach, considering both the formulation and the substrate preparation. Here are some optimization strategies to enhance adhesion:

Proper surface preparation is a fundamental step in ensuring strong adhesion. Depending on the substrate, surface treatments like cleaning, etching, or priming can greatly improve the bonding between the coating and the material. Some common surface preparation methods include:

· Cleaning: Removing contaminants like oils, dust, or moisture from the surface is essential for good adhesion. This can be done using solvents, detergents, or specialized cleaners.

· Surface Activation: Techniques like plasma treatment, corona discharge, or flame treatment can be used to increase the surface energy of low-energy substrates like plastics, making them more receptive to UV coatings.

· Priming: For some substrates, applying a primer layer can improve adhesion by providing a better bonding surface for the UV coating.

Selecting the right formulation is critical for achieving optimal adhesion. This includes using the appropriate resin system and adding the right amount and type of adhesion promoter. To further optimize adhesion:

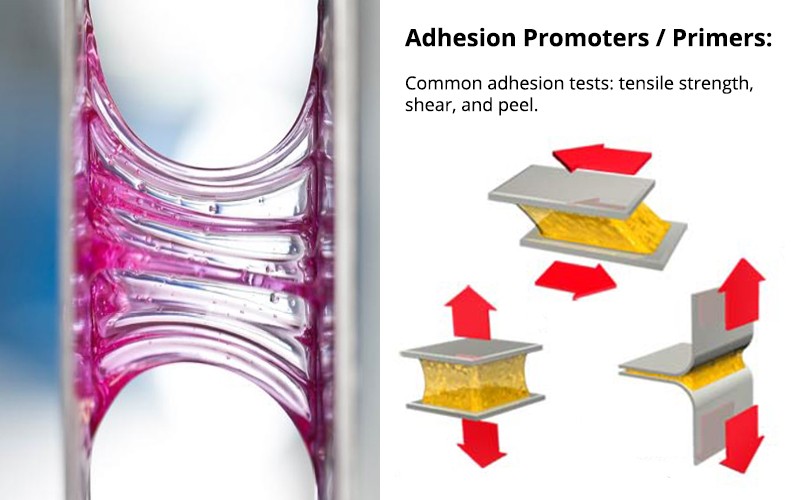

· Use of Adhesion Promoters: As mentioned earlier, using the right adhesion promoter is key for ensuring a strong bond between the coating and the substrate. The correct promoter will depend on the substrate material and the resin system.

· Optimize Cure Conditions: The curing process plays a vital role in adhesion. Over- or under-curing the UV coating can result in poor adhesion. Ensure that the curing time and intensity of the UV light are optimized for the specific formulation and substrate.

· Balance Resin and Additives: The combination of resin and additives, such as plasticizers or stabilizers, must be carefully balanced to avoid reducing the adhesive properties of the coating. It's important to ensure compatibility between all components of the formulation.

Environmental factors such as humidity, temperature, and exposure to chemicals can influence the adhesion of UV coatings. For instance, high humidity can affect the curing process and cause poor adhesion. Testing the coating in real-world conditions and making adjustments to the formulation as needed will help improve adhesion under various environmental stresses.

Adhesion is one of the most critical factors in the performance of UV coatings, and improving it requires a careful approach that considers both the substrate and the coating formulation. By using effective adhesion promoters, optimizing the formulation, and properly preparing the substrate, manufacturers can ensure strong and durable adhesion that enhances the quality and longevity of their UV-coated products. Whether applied to metal, plastic, glass, or wood, UV coatings with enhanced adhesion provide superior protection, durability, and aesthetics, making them ideal for a wide range of industries and applications.

#UVCoating #SurfacePreparation #AdhesionImprovement #IndustrialCoatings #CoatingTechnology #UVResin

#SurfaceTreatment #CoatingSolutions #SmartManufacturing #MaterialScience #AdhesionPromoter

#PlasmaTreatment #CoronaDischarge #FlameTreatment #UVCuringTechnology #CoatingFormulation

#PrimerApplication #ResinOptimization #UVCoatingTip #IndustrialUV #ImproveAdhesion #CleanBeforeCoating

#OptimizeCuringTime #LowEnergySurfaceSolution #PlasticSurfaceTreatment #DurableCoating #UVPrimerHack

#BondingChallenge #UVAdditives #CuringMatters

2022-08-03

2025-01-06