UV curing technology has evolved significantly over the years, with innovations such as UV LED curing systems, low migration UV systems for food packaging, and advancements in sustainability playing a major role in shaping its future.

In this article, we'll explore the latest trends in UV curing technology, including the development of UV LED systems, the application of low migration UV systems in food packaging, and the role of UV technology in sustainability.

UV LED curing technology has rapidly emerged as a game changer in the UV curing industry due to its numerous advantages over traditional mercury vapor lamps. The growing trend toward UV LED curing is driven by improvements in energy efficiency, environmental concerns, and the need for faster curing processes in various industries.

UV LED curing systems consume significantly less energy than traditional mercury-based UV lamps. LED systems convert more electricity into UV light rather than heat, making them highly efficient. This efficiency reduces operational costs and contributes to a more sustainable production process.

UV LED curing systems have a much longer lifespan compared to traditional mercury lamps. While mercury lamps require frequent replacement and maintenance, LED lamps can last tens of thousands of hours, reducing downtime and maintenance costs. This increased longevity makes UV LED systems an attractive option for high-volume industrial applications.

Unlike mercury lamps, which take time to warm up, UV LED lamps can be turned on and off instantly. This feature improves the flexibility of production lines, enabling faster switching between processes and reducing idle times.

UV LED systems are free of hazardous materials, such as mercury, and produce less heat, making them safer to use in various applications. This makes UV LED curing systems more environmentally friendly and compliant with stringent environmental regulations.

The development of UV LED curing systems is expected to continue advancing, with further improvements in light output, efficiency, and versatility. As these systems become more affordable and widely adopted, they will likely replace traditional UV curing methods in more industries.

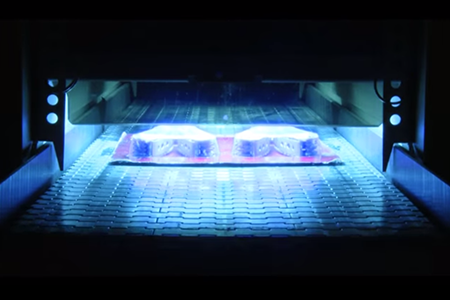

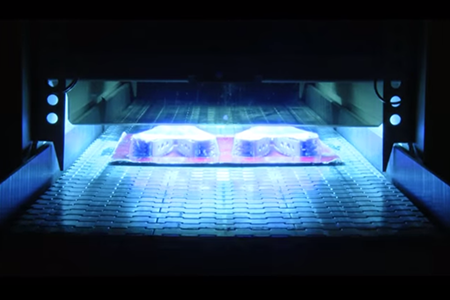

Low migration UV systems are designed to minimize the migration of chemicals from the coating or ink into the food products they come into contact with. This is particularly important in the food packaging industry, where ensuring the safety of packaging materials is critical to consumer health.

In the food packaging industry, safety regulations and standards for migration limits are becoming more stringent. Traditional UV inks and coatings may contain chemicals that could migrate from the packaging material into food. Low migration UV systems are specifically formulated to address these concerns, ensuring that only safe levels of substances are present in the packaging materials.

Low migration UV systems comply with international standards, such as those set by the European Food Safety Authority (EFSA) and the U.S. Food and Drug Administration (FDA). These systems are carefully formulated to ensure that any potential migration of chemicals from inks and coatings does not exceed the allowable limits set by regulatory authorities.

Despite their emphasis on safety, low migration UV systems do not compromise on the performance or durability of the packaging. These systems provide excellent adhesion, abrasion resistance, and gloss, ensuring that the packaging maintains its aesthetic appeal and protective qualities while being safe for food contact.

As consumer awareness of packaging safety continues to rise, the demand for low migration UV systems will increase. The ability to provide food-safe packaging without sacrificing performance or sustainability will drive innovation in this area.

UV curing technology plays a significant role in promoting sustainability across various industries by offering environmentally friendly alternatives to traditional processes.

One of the key environmental benefits of UV curing is the reduction of volatile organic compound (VOC) emissions. Traditional solvent-based coatings release harmful VOCs into the air during curing, contributing to air pollution and health risks. UV curing systems, on the other hand, require no solvents and release little to no VOCs, making them a safer and more sustainable alternative.

UV curing systems, particularly UV LED curing, are much more energy-efficient than traditional thermal curing methods. UV LEDs operate at lower temperatures, reducing the need for excessive energy consumption. In industries such as automotive, packaging, and electronics, UV curing can significantly reduce energy usage, lowering carbon footprints and production costs.

UV curing systems are highly efficient in terms of material usage. With UV coatings, inks, and adhesives, there is less material waste because the curing process is so precise. In contrast, traditional thermal curing often leads to excessive waste and longer curing times, which contribute to inefficiencies in production processes.

As part of the growing trend toward sustainability, there is increasing interest in developing UV curing systems that utilize renewable, bio-based materials. These systems offer the performance of traditional UV coatings while being more eco-friendly. Many UV resins and additives are now formulated with sustainable ingredients, reducing the environmental impact of the final products.

UV technology is also contributing to the concept of a circular economy, where products and materials are reused, refurbished, and recycled. UV coatings are used in applications that support recycling processes, such as in the coating of recycled paper and packaging materials. Additionally, the ability to cure coatings quickly and precisely supports processes where materials are used more efficiently and can be recycled without additional contamination.

The future of UV curing technology is bright, with continued advancements in UV LED curing systems, low migration UV systems for food packaging, and the role of UV technology in supporting sustainability. As industries move toward more sustainable practices, UV curing technology offers a pathway to reduce environmental impact while maintaining high-quality performance. From energy-efficient LED systems to safe and durable food packaging, UV curing technology will continue to play a key role in shaping a more sustainable future across various industries.

#UVCuring #UVCuringTechnology #UVCoatings #UVCuringSolutions #UVResins #UVPrinting #UVAdhesives

#FastCuring #UVCurable #UVInnovation #UVProtection #AdvancedCoatings #SurfaceProtection #EfficientCuring

#UVIndustry #UVTech #IndustrialCoatings #UVPerformance #EcoFriendlyCuring #NextGenCoatings

2022-08-03

2025-01-06