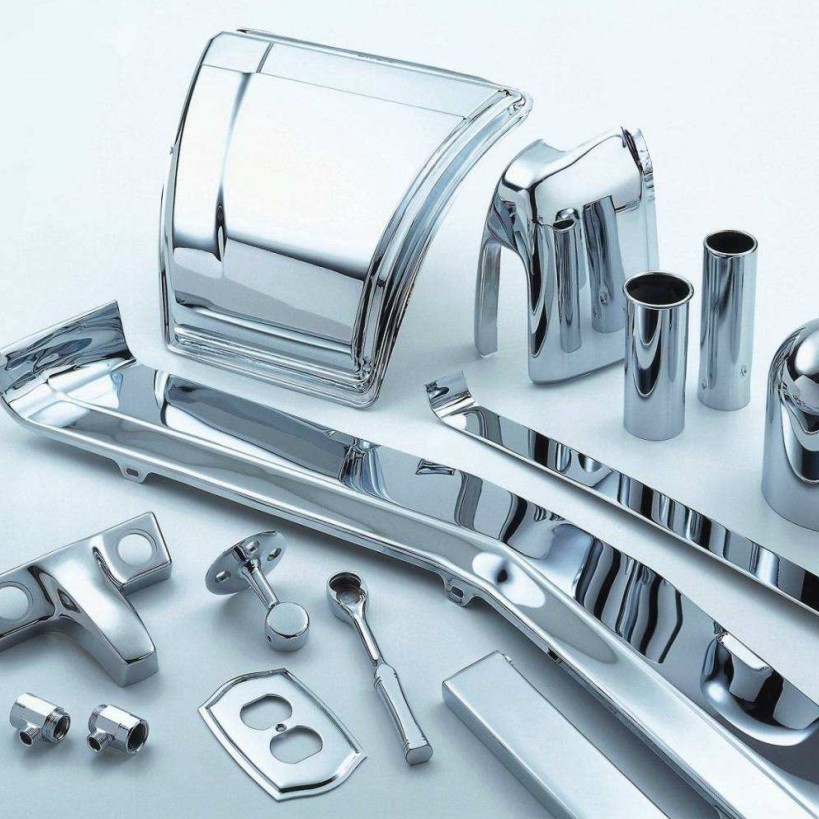

Below are our most popular resins for vacuum plating.

L-6040 is a specially modified pure acrylic resin. The product has the advantages of good flexibility, high curing rate, very low shrinkage, good adhesion to metals, and good compatibility with dyes and color pastes.

| Appearance | Colorless transparent liquid |

|---|---|

| Viscosity (25ºC,CPS) | 3,500 - 7,000 |

| Chroma (Gardner) | ≤1 |

| UV component (%) | 100 |

| Density (g/cm3, 25℃) | 1.1 ± 0.1 |

| Acid value (mg KOH/g) | ≤5 |

| Refractive index | 1.459 |

| Shore hardness | 72A |

| Functional group | 2 |

UV vacuum coating finish, TPU UV vacuum coating, UV high gloss varnish, UV plastic coating, UV ink, UV silk screen varnish, paper varnish, etc.

L-6131 is modified epoxy acrylate resin, with hard but not brittle, high leveling, high reaction active, non-yellowing and other characteristics. Highly recommended for vacuum coating primers, topcoats, varnishes UV, nail polish primer, surface glue, adhesive, silk screen varnish, 3D printing and other light curing field. It can significantly improve the gloss, hiding power, fullness and abrasion resistance of the paint film.

| Appearance | Clear transparent liquid |

|---|---|

| Viscosity (25ºC,CPS) | 35,000 - 45,000 |

| Chroma (Gardner) | ≤1 |

| UV component (%) | 100 |

| Acid value (mg KOH/g) | ≤1 |

| Refractive index | 1.546 |

| Shore hardness | 86D |

| Functional group | 2 |

It is widely used in vacuum plating primer, UV wood coating, UV ink, UV plastic varnish, etc.

L-6200C is 2-functional UV polyurethane resin with good plating property, recommended for light-curing applications such as coatings, inks, and adhesives. As a free radical curing host film-forming resin,L-6200C has excellent flexibility and curing speed, excellent adhesion on various plastic substrates, and also has good bonding force between vacuum coating layers. It has good low-energy curing and drying performance on aluminum plating process primers. The aluminum film of the reflective cup product does not emit blue fog when irradiated. The composition of the coating formula is resistant to folding, no bursting and no cracking on miscellaneous materials, PP, PE, PVC attached substrates, the paint film has good hiding power and maintains good wetting and leveling properties.

| Appearance | Light yellow transparent liquid |

|---|---|

| Viscosity (25ºC,CPS) | 22,000 - 35,000 |

| Chroma (Gardner) | ≤2 |

| UV component (%) | 100 |

| Acid value (mg KOH/g) | ≤1 |

| Refractive index | 1.474 |

| Shore hardness | 60A |

| Tensile strength (MPa)(ASTM D882) | 12.6 |

| Elongation at break (%)(ASTM D882) | 51.7 |

| Functional group | 2 |

vacuum plating primer, UV touch paint, UV ink, UV plastic varnish, 3D printing, etc.

L-6203 is a highly efficient polyurethane resin, recommended for applying on coating, ink, adhesive curing application area. As a free radical curing major film formation resin, L-6203 promotes overall performance and stretchability than L6200C, with good adhesive on various plastics, excellent adhesion between vacuum plating films, extremely excellent covering ability on various metal coatings, good fullness on rugged surfaces and defective substrates, the coating surface not easy to collapse after water boiling and non yellowing, suitable for higher demand on coating ink system application.

| Appearance | Light yellow clear transparent liquid |

|---|---|

| Viscosity (25ºC,CPS) | 65,000 - 85,000 |

| Chroma (Gardner) | ≤2 |

| UV component (%) | 100 |

| Acid value (mg KOH/g) | ≤1 |

| Refractive index | 1.479 |

| Shore hardness | 66A |

| Tensile strength (MPa)(ASTM D882) | 5.1 |

| Elongation at break (%)(ASTM D882) | 61.2 |

| Functional group | 2 |

Widely used in vacuum plating primer, UV nail polish primer, color glue, UV ink, UV plastic varnish, etc.

L-6410 is a specially modified 4-functional polyurethane acrylate resin with high reactive activity. The product has low shrinkage, good adhesion, good resistance to hand sweat and cosmetics, and solvent diluting resistance. It has excellent adhesion to various plastic substrates such as PC, ABS, PMMA, TAC, etc. It can also be used alone to obtain good adhesion, and also has good adhesion properties to paper, wood, metal and other substrates. Can be used as main resin of various UV coatings and vacuum-plated UV finish with high requirements on wear resistance.

| Appearance | Colorless transparent liquid |

|---|---|

| Viscosity (25ºC,CPS) | 2,000 - 6,000 |

| Chroma (Gardner) | ≤1 |

| UV component (%) | 75±2 |

| Density (g/cm³,25℃) | 1.1±0.1 |

| Acid value (mg KOH/g) | 4-8 |

| Refractive index | 1.476 |

| Functional group | 4 |

Various high requirements coatings: UV vacuum coatings, UV plastic coatings, UV silk varnish, various metal UV, various UV ink, etc.

L-6460 It is a specially modified highly reactive 4-functional urethane acrylate resin. The product has low shrinkage, good adhesion, resistance to hand sweat, good cosmetic resistance, and solvent resistance. It has excellent adhesion to various plastic substrates such as PC, ABS, PMMA, TAC, etc. It can also obtain good adhesion when used alone, and also has good adhesion to paper, wood, metal and other substrates. It can be used as the main resin for various UV topcoats and vacuum plating UV topcoats with high requirements such as vibration wear resistance for 2 hours.

| Appearance | Colorless transparent liquid |

|---|---|

| Viscosity (25ºC,CPS) | 1,000 - 2,500 |

| Chroma (Gardner) | ≤1 |

| UV component (%) | 80±2 |

| Density (g/cm³,25℃) | 1.1±0.1 |

| Acid value (mg KOH/g) | 2-6 |

| Refractive index | 1.481 |

| Functional group | 4 |

Various high requirements coatings: UV vacuum coatings, UV plastic coatings, UV silk varnish, various metal UV, various UV ink, etc.

L-6605 Low-shrinkage 6-functional UV polyurethane resin, recommended for hard high-performance light-curing applications such as coatings, inks, inkjet, 3D printing, etc., with high cross-linking density, hard but not brittle paint film, good adhesion, high leveling gloss , yellowing resistance, good wetting and leveling properties, weather resistance, easy to extinction.

| Appearance | Colorless transparent liquid |

|---|---|

| Viscosity (25ºC,CPS) | 75,000 - 120,000 |

| Chroma (Gardner) | ≤1 |

| UV component (%) | 100 |

| Acid value (mg KOH/g) | ≤1 |

| Refractive index | 1.492 |

| Shore hardness | 86D |

| Functional group | 6 |

It is widely used in UV high-gloss varnish, UV plastic coating, UV vacuum plating primer, UV screen printing varnish, UV transfer oil, etc.

L-8413 modified polyurethane acrylate is recommended for use in light-curing products such as coatings, inks, and adhesives. Provides very good adhesion, fast curing speed and wetting and leveling on various substrates such as PP, PE, PET and metal after treatment. It is used in vacuum plating primers and topcoats, metal and plastic varnishing UV coatings, inks and adhesives for various structures. It has excellent performance in various tests of water resistance, chemical resistance and temperature resistance.

| Appearance | Light yellow clear transparent liquid |

|---|---|

| Viscosity (25ºC,CPS) | 10,000 - 14,000 |

| Chroma (Gardner) | ≤2 |

| UV component (%) | 100 |

| Acid value (mg KOH/g) | ≤7 |

| Refractive index | 1.5 |

| Functional group | 3 |

Widely used in UV adhesives, UV inks, UV transfer adhesives, UV plastic coatings, UV vacuum plating primers, etc.

If you are looking for any materials for vacuum plating, pls inform us your detailed property requirements, we will recommend the most suitable items accordingly, thank you.

#UVResin #HighPerformanceUVResin #TransparentUVResin #FastCuringUVResin #ArtCraftUVResin #DIYUVResinProjects #JewelryMakingUVResin #EpoxyUVResin #UVResinForCoating #WaterproofUVResin #VacuumPlatingTechnology #EcoFriendlyPlating #SurfaceTreatmentTrends #VacuumCoatingApplications #PremiumMetalFinish #PlatingIndustryInnovation #GreenManufacturingTech #VacuumCoatingEquipment #PlatingProcessUpgrade #FutureOfVacuumPlating

2022-08-03

2025-01-06