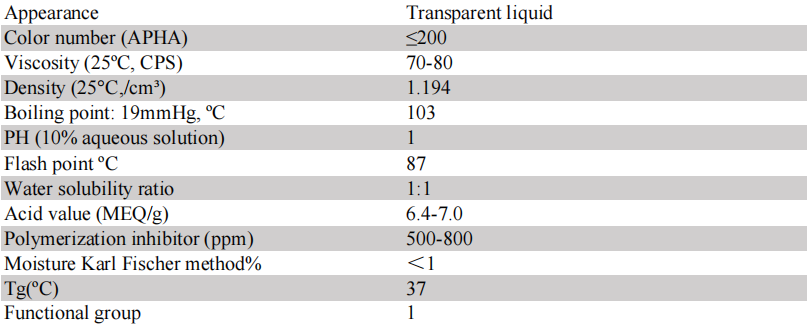

L-61045 β-Carboxymethacrylate is a reactive acrylic double bond that is easily copolymerized with vinyl and acrylic monomers in emulsion polymerization and radiation curing systems. Having a lower glass transition temperature can effectively promote adhesion and improve the stability of the emulsion. Having longer side carboxylic acid chains gives good flexibility and promotes more effective interaction between the polymer and the substrate, thus enhancing the adhesion and peel strength. This strength tends to increase with time. β-CEA cross-links with amino, hydroxyl, epoxy, isocyanate functional groups and other structures, and is suitable for water-based, solvent-based and 100% solid systems. Low Tg value (37℃), can be used to adjust the hardness of paint or improve the bonding strength of pressure-sensitive adhesive.

Low odor, high hydrolysis resistance, low shrinkage, good toughness

Widely used in photo-curing polymerization fields such as UV coatings, UV 3D printing inks, UV screen printing inks, UV adhesives, UV glues, and UV inkjet.

25KG/200KG per barrel

L-61045 is used in water-based coatings to enhance scratch and scrub resistance.

--------------------------------------------------------------------------------------------------------

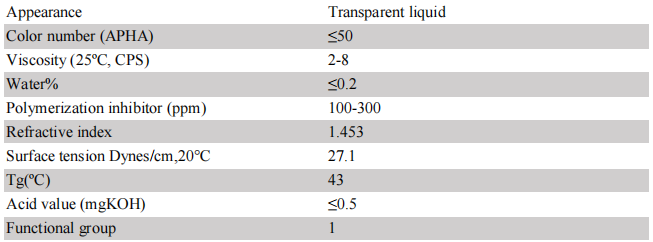

L-61055 acrylic monofunctional photocurable monomer. It has the characteristics of low odor and little irritation to the skin, low viscosity and strong dilution ability, low surface tension and good wettability of the substrate, high glass transition temperature and good balance between hardness and toughness. It has outstanding wettability and adhesion promotion effects on various plastic substrates.

Low odor, high hydrolysis resistance, low shrinkage, good toughness

Widely used in photocuring polymerization fields such as UV coatings, UV 3D printing inks, UV screen printing inks, UV adhesives, UV glues, and UV inkjet.

25KG/200KG per barrel

L-61055 has light color and good compatibility; it wets the substrate well and can be used as a solubilizer.

2022-08-03

2025-01-06