Used in various plastic films and papers such as PVC, PC, PET, wooden floors, leather, etc. can be coated with decorative surfaces to soften the skin.

Chat Now Download TDSDescription

SQ-720009 UV nano-excimer skin-feel coating uses nano-minute technology to use the energy emitted by the excimer lamp to form wrinkles on the surface of the paint film after curing. The resulting paint film has a skin touch and makes the decorative surface more delicate. . Mainly used for hardening treatment on PVC, wooden floor and film surfaces. It can be applied by spraying or roller coating. After the coating forms a film, it has good adhesion to the substrate and can protect the surface of the coated material for a long time. The coating process is simple and the production efficiency is high. The coating has low curing shrinkage, extremely high hardness and excellent wear resistance.

Technical data

| Test items | Test Data |

|---|---|

| Appearance | Milky white liquid |

| Viscosity (apply 4 cups/25℃) | 400-800 |

| Solid content (%) | 100 |

| Density (g/cm³, 25ºC) | 0.90±0.05 |

| Hardness (1Kg force load) | > 1H |

| Gloss (60° angle gloss meter) | 2-5° |

| Curing energy (mercury lamp, mj/cm²) | 600-1000 |

| QUV resistance performance | Over 400h |

| Anti-graffiti (Zebra oil-based pen) | Generally |

| Water contact angle | Generally |

| Note: The above performance parameters can be customized according to customer requirements | |

Product Features

Excellent scratch resistance and anti-fouling / anti-fingerprint performance

Soft, smooth touch akin to baby skin, with a very delicate texture

Matte level up to 2°, resistant to nail scratches

Good chemical resistance and weatherability

Applications

Various plastic films and papers such as PVC, PC, PET, wooden floors, leather, etc. can be coated with decorative surfaces to soften the skin.

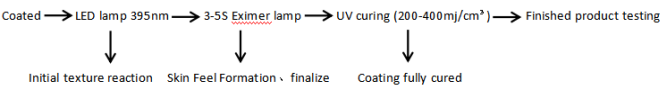

Construction Process

Precautions

1. This product is pre-diluted to a solid content and viscosity suitable for roll coating and does not require further dilution before use. If a higher solid content is required, we can provide custom high-solid products and corresponding diluents according to the customer’s specific requirements.

2. This product contains flammable components. Take proper precautions against fire during transportation, storage, and use.

Storage Conditions

To prevent premature polymerization due to the high reactivity of this product, keep it tightly sealed and store away from heat sources and direct sunlight. It is recommended to maintain storage temperature below 30 °C. Unused product should be promptly resealed and must not be left open. Under ventilated conditions at 25 °C, the product has a safe storage period of 6 months. Available packaging: 1 kg / 5kg / 25 kg per drum

Tips:SQ-720009 excimer UV varnish has very good soft touch skin feel, delicate baby-like smoothness, and good scratch resistance.

Note: Technical data represents typical values only. In view of the differences in formulas, production process, conditions, all the above statements must be adjusted according to the actual situation, our company does not make any promises. Our company reserves the right to reform its products without prior notice of any changes.

Contact Person: Yuki

Tel: +86 18027002837(WhatsApp)

Email: service@lencolo37.com